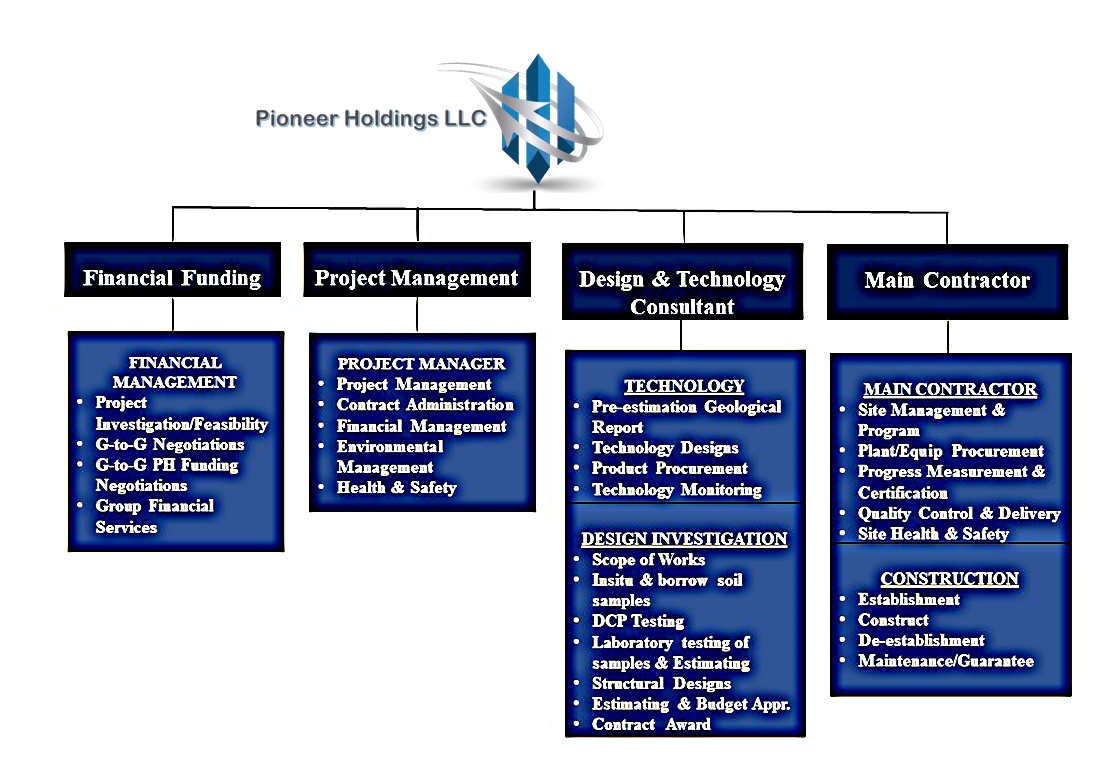

The “EPCF” Turnkey Model provides the following:

- “Engineering” – In-house employment of Geological Investigation Services, Professional Civil, Mechanical Engineering & Quantity Surveying Services,

- “Procurement” – The acquisition of “right-fit” technologies, methodologies, materials & human resources required to deliver the complete works

- “Construction” – The delivery of a high standard product, at a competitive price, on time

- “Funding” – Through “G-to-G” negotiations, our Financial Partners can offer and support the customized package which best fits our Clientele requirements

A. GRAVEL ROAD/BASE COURSE STABILIZING (Soil Tech Mkiii Polymer-Based Road Stabilizers):

- All-Weather, high traction unsurfaced gravel roads providing 24/7 use

- Stabilized insitu base course – No need to import selected materials from quarry or borrow

- Design capable of carrying >300t single axle loads

- Stormwater penetration into base course reduced and run-off into side drains improved.

B. COLD PREMIX SURFACING (Asphal Tech Polymer-Based Surfacing):

- Technology allows for 20-40mm thick surfacing to be laid using locally sourced aggregate which reduces costs considerably

- “AsphalTech” surfacing will not bleed, shrink, crack or shear under extreme temperatures and traffic loads

- Maintenance costs are considerably reduced

C. SPECIALIST & GENERAL ROAD WORK SERVICES:

- Stormwater design & construction including structural concrete culverts

- River bridge construction & other structural concrete services

- Road marking, signage, lighting, safety barriers

- Seamless “Infra-red” pothole repair technology

Polymer-Based Soil Stabilizers

- State of the art polymer stabilizing technology is applied to new or existing gravel roads capable of single axle loads of > 300t

- All-weather unsurfaced gravel roads benefitting from uninterrupted 24/7 use

- Improved quality of road & drive ability reduces operating

- costs, tyre wear & tear whilst improving driver safety

- Technology is used on insitu materials which reduces the need to import specified materials from borrow or commercial source

- 30% reduction in construction costs & 50% reduction in

- construction time & 300% extended longevity

- Up to 6% saving on CO₂ emissions impacting on the environment

Polymer-Based Dust Suppressants

- Sustainable gravel road dust suppressant technology reducing dusting by >85%

- Technology does not require daily spray application

- of “Dust-Tech”

- Massive water savings (up to 80%)

- Highly cost effective for unsurfaced gravel road network

- Nano-polymer technology provides all-weather ride ability promoting driver safety & lower application costs

- Environmentally sustainable

Technical Benefits:

- Specially Designed Premix Bitumen For Africa

- Permanent Pothole Repair Solution

- Fully Fitted Vehicle

- Existing Material Re-Used – No Waste

- Speed, Safety & Efficiency

- Economical

- No Dust

- No Saw Cutting

- No Mechanical Excavating/Demolition

- Open to Traffic Immediately

- 2 Year Warrantee

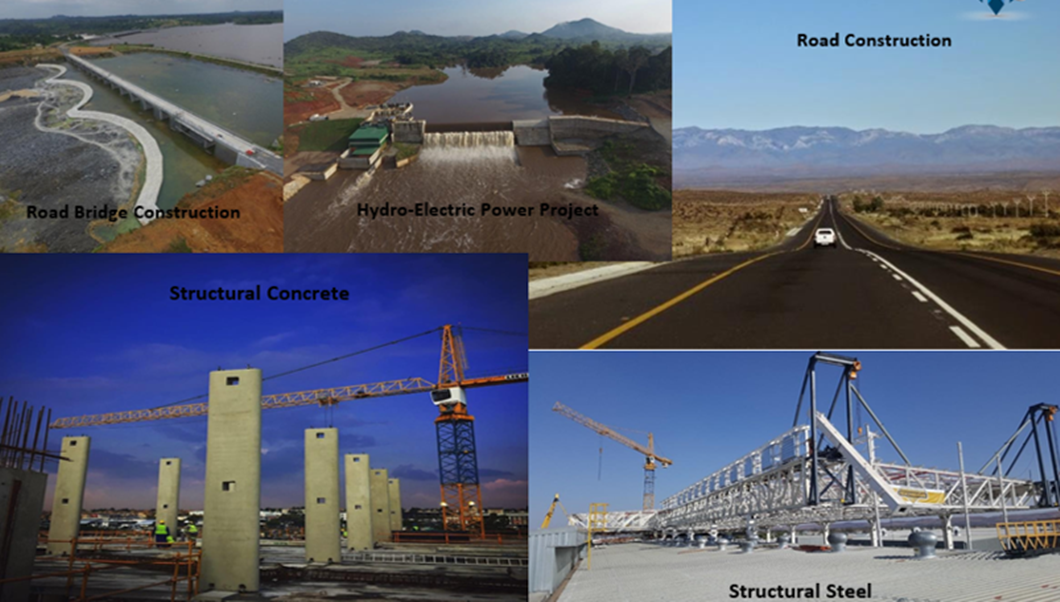

Our focus on employing a highly qualified & motivated human resource component within our business has enabled us to undertake & successfully complete projects involving:

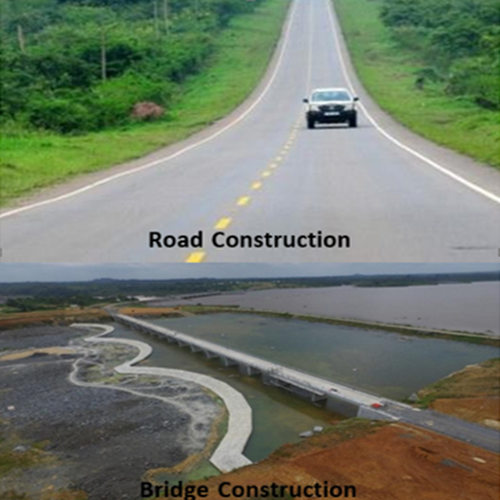

- Gravel & Surfaced Road Construction

- River/Road/Rail Bridge Construction

- Dams & Hydroelectric Power Plants

- Structural Concrete Water Towers

- Structural Steel Gantries & Bridges

- Solar Energy Plants Providing Alternative Energy To The Grid